Additional Services

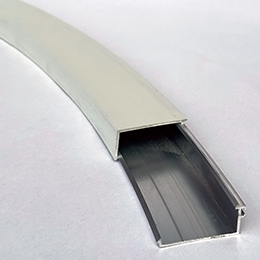

Vinyl Curving

At Rimac, we are also able to curve various types of plastic. Oftentimes, we are asked to curve vinyl, PVC or thermal break type components, including polyamide plastic thermal struts, to accompany the metal parts we are already curving. Advanced glazing systems, for example, often contain PVC components which act as thermal barriers or water deflectors, which help increase the performance of the system.

By curving the plastic components in house, we can ensure they meet the same quality standards our customers have come to expect from Rimac. This saves our customers time and money: curved plastic and metal components can be sourced from a single supplier, saving time coordinating multiple vendors and saving on freight. Rimac truly is a one-stop shop for curved components.

Final Cutting & Mitering

Final cutting and mitering services are also offered at Rimac. We know that working with complex curved shapes adds an additional challenge to any project. We work with curves everyday. At Rimac, we're happy to provide parts back to you final cut and mitered to your exact specifications. Not only does this help avoid costly cutting errors on your end, but also aleviates time consuming additional steps within your production line.

At Rimac parts can be cut to length, mitered, drilled, tapped, notched, punched, and even contoured. This allows us to supply our customers with complete parts ready for assembly.

Let Rimac show you how your most complex parts can be supplied complete and ready for assembly.

Please download Rimac's helpful Ordering Guide to help you when ordering. Download Here

"At Rimac personal service is what we are about"

Back To Services