Stretch Forming

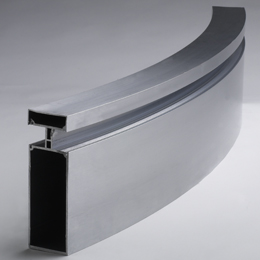

When applicable, Stretch Forming methods provide several unique advantages over pure bending and other types of metal forming. Stretch Forming provides an extremely high quality part, with minimal cross sectional distortion and little or no deterioration of the materials finish.

Stretch Forming machines operate by stretching a part around a forming die. This process increases the metal's yield strength and actually results in a stronger part. Since Stretch Forming machines also keep the metal under constant tension, they minimize imperfections. Stretch Forming machines also perform a task in one step that would otherwise require several machines and multiple steps, improving efficiency and saving time and money.

Stretch Forming allows for production runs of parts to be cost effective compared to other methods of curving. Stretch Forming also offers elongation control for unparalleled accuracy and consistency and allows for non symmetrical profiles to be formed without twisting. Stretch Forming allows the minimum bend radius to be generally 2-3 times greater than other forming/metal bending methods.

At Rimac parts can be cut to length, drilled, tapped, notched, punched, and even contoured. This allows us to supply our customers with complete parts ready for assembly.

Let Rimac show you how your most demanding applications are easily achieved.

Please download Rimac's helpful Ordering Guide to help you when ordering. Download Here

"At Rimac personal service is what we are about"

Back To Services